Modular Clean Room Panels – High-Quality, Prefabricated Solutions for Advanced Industries

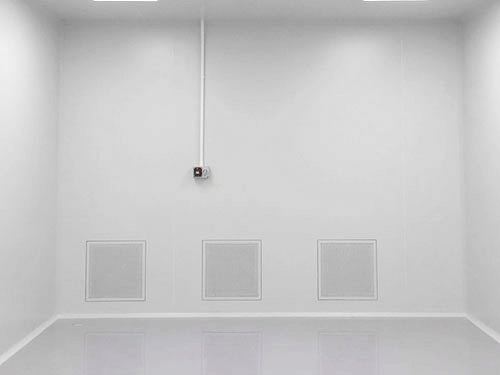

We specialize in prefabricated modular panel systems that provide fast-track construction solutions, reducing installation time while maintaining precision, efficiency, and structural integrity. Designed to meet highly controlled environments, our panels ensure airtight sealing, contamination prevention, and enhanced energy efficiency.

Why Choose Our Modular Clean Room Panels ?

✔ Fast & Easy Installation – Prefabricated wall and ceiling panels enable quick assembly, minimizing downtime and labor costs.

✔ Customizable for Any Layout – Our modular system accommodates various clean room configurations, with pre-engineered cutouts for lighting, HVAC, filters, and integrated doors/windows.

✔ Future-Proof & Scalable – As clean room technology evolves, our panels can be modified, expanded, or upgraded to support new equipment or manufacturing process adjustments.

✔ Expert Engineering & Full Project Support – Our team consists of clean room panel design, engineering, and installation specialists, guiding customers step by step from planning to execution to ensure seamless project completion.

✔ ISO 9001:2015 Certified Quality – As a company committed to excellence, we never compromise on quality and strictly adhere to ISO 9001:2015 certification standards.

✔ Innovative R&D for Advanced Clean Room Technology – Our dedicated R&D department is continuously developing new technology and manufacturing innovations to keep up with the fast-changing clean room industry and meet the most demanding customer requirements.

At Square Panel System Co., Ltd., we deliver cutting-edge clean room solutions that enhance efficiency, performance, and reliability for industries that require precision, sterility, and adaptability. Whether for pharmaceutical laboratories, biotech research, semiconductor manufacturing, or food processing, our high-performance modular clean room panels provide a future-proof, cost-effective, and long-lasting solution.

- Airtight – Prevents air leakage and ensures a controlled environment.

- Waterproof – Resistant to moisture, preventing damage and contamination.

- Flush Surface – Smooth, seamless design for easy cleaning and hygiene control.

- Heat Insulation – Provides thermal efficiency, reducing energy consumption.

- Self-Supporting & Dismountable – Offers structural stability while allowing for easy disassembly and reconfiguration.

- Durability – Built for long-lasting performance in demanding environments.

- Particle-Free – Designed to minimize particle generation, ensuring cleanliness.

- Easy to Clean – Smooth surfaces for effortless maintenance and sanitation.

- Chemical Resistant – Withstands exposure to harsh cleaning agents and chemicals.

- Cost-Effective – Optimized for efficiency, performance, and long-term value.

Wall System Features

- Fast & Easy Installation – Prefabricated panels enable quick assembly and reduce construction time.

- Concealed Electrical Wiring – Integrated within the panel for a clean and seamless appearance.

- Self-Supporting & Dismountable System – Provides structural integrity and easy reconfiguration for future modifications.

- Flush Surface with Corner Coving Finishing – Eliminates gaps and edges, ensuring optimal hygiene.

- Flexible Layout & Expansion – Allows for cleanroom reconfiguration and future growth.

- Return Air Riser Options – Available as either external or built-in panel systems, complete with washable prefilters and removable grilles for efficient airflow management.

-

Single-Piece Wall Round Corner – Designed for seamless integration, durability, and a high-quality finish.

Ceiling System

- Walkable & Serviceable – Designed to support maintenance access for HVAC systems, lighting, and filtration units.

- Concealed Suspension – Ensures a clean, seamless appearance while enhancing structural stability.

- Interior Flush Surface – Provides a smooth, hygienic, and easy-to-clean finish for contamination-free environments.

- Flexible for On-Site Cutouts – Easily accommodates modifications for lighting, HEPA filters, and other cleanroom components.

Window System

- Available in Two Fixed Window Types:

✔ Single Glazed Window – Provides a clear, durable viewing option for controlled environments.

✔ Flush Mounted & Double Glazed Window – Designed for enhanced insulation and airtight performance. - Nitrogen-Filled for Condensation Prevention – Ensures crystal-clear visibility and moisture resistance in cleanroom applications.

- Standard Size: 1,160mm (W) x 1,000mm (H) – Custom sizes available upon request.

Clean Room Door

- Available in Hinged & Sliding Door Options – Designed for various cleanroom applications.

- Custom-Made Opening Sizes – Tailored to fit specific project requirements.

- Standard Sizes:

✔ Single Leaf Door : 900 x 2,100 mm., 1,200 x 2,100 mm.

✔ Double Leaf Door : 1,800 x 2,100 mm.

- Flush Type Hinged Door – Seamless design for cleanroom environments.

- Electrical Interlock System Available – Enhances security and controlled access.

- Flush-Mounted, Built-In Viewing Window – Provides clear visibility without compromising airtightness.

- Automatic Drop Seal Available – Ensures optimal sealing to prevent contamination.

-

Stainless Steel Handle & Door Lock – Durable, corrosion-resistant, and hygienic for cleanroom applications.